Efficient solutions for Ferrous and Aluminium component manufacturing

Strategically located facilities in close proximity to customer locations

Enduring partnerships with Indian and International customers

Committed to highest standards of governance and ethical conduct

LEARN MORE ABOUT REVENT

About Us

When it comes to delivering high-end world class automotive and non-automotive sectors manufacturing solutions, Revent is geared with state-of-the-art manufacturing technology with a sharp emphasis on design, development, engineering, machine construction, and automation skills. Driven by a highly qualified team with extensive experience and expertise across processes, Revent lives up to the faith and trust that our esteemed customers have placed in us.

Revent was born consequent to the acquisition of two former Amtek group Companies (Amtek Auto Limited and Castex Technologies Limited) by a US based investment fund- DVI (Deccan Value Investors)

The two entities post this acquisition are enlisted below:

Revent Precision Engineering Limited

Revent Metalcast Limited

DVI, has led to a complete transformation and strengthening of the businesses and complete financial settlement of all the past liabilities. DVI has infused fresh capital in the company to strengthen the manufacturing capabilities, new technology, expanding product range and capacity, keeping long term and sustainable growth, as its primary objective with customer centricity at its core.

Revent Group companies offer multi-technology solutions in Ferrous and Aluminium based Casting, Forging and Machining processes. The existing product range cater to the entire range of mobility solutions, servicing a diversified customer base ranging from Passenger vehicles, Commercial vehicles, Construction Equipment, Farm Equipment, Two Wheelers and Three Wheelers and other non-automotive sectors like Railways. Our roadmap includes expanding product offerings to include the Electric and Hybrid mobility segments.

"Precision Engineering"

"High Performance"

"Complete Solution Provider"

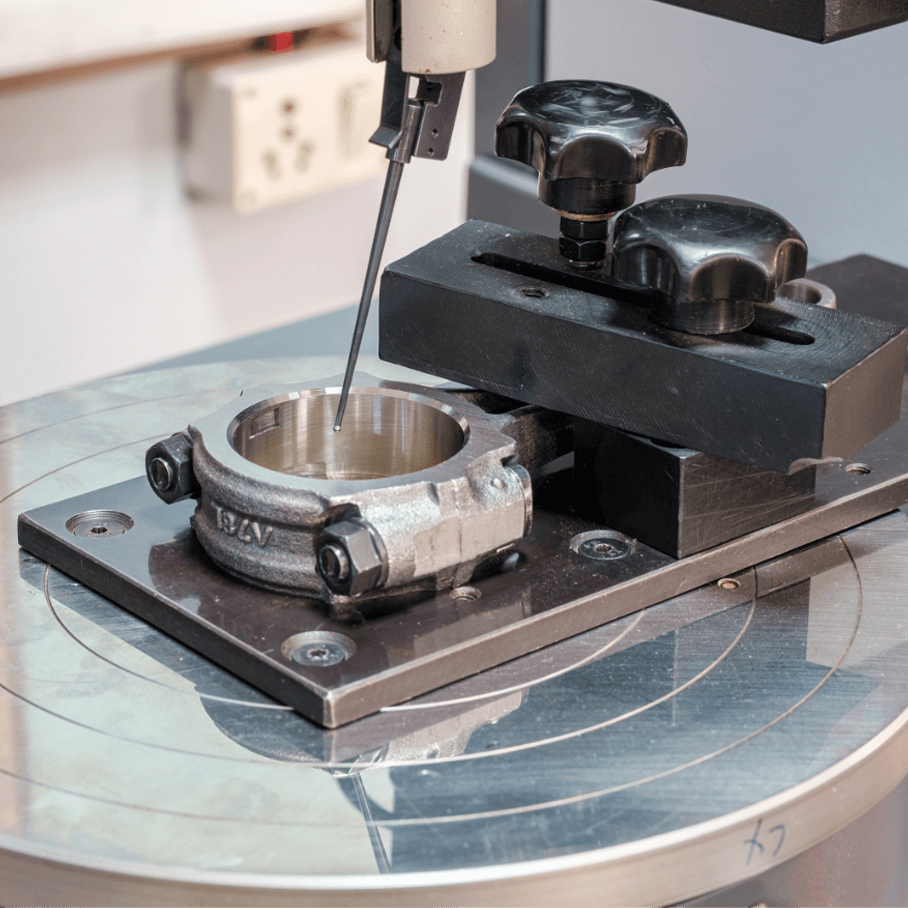

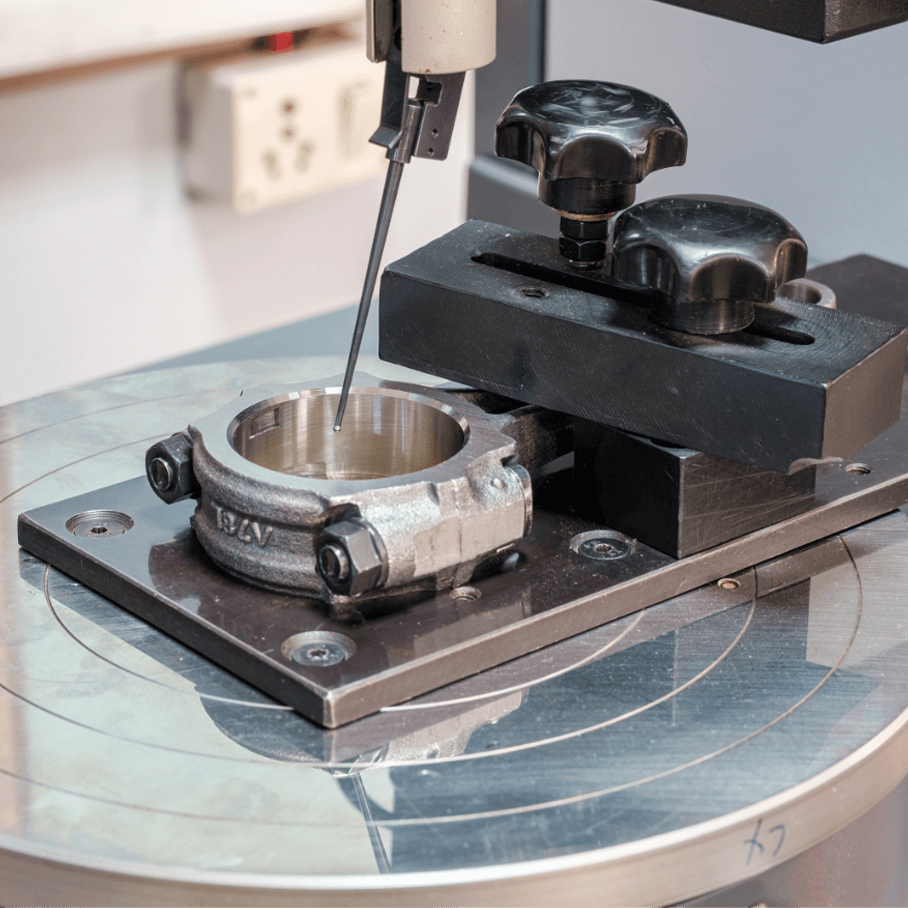

"Best in class Testing Facility"

"High Manufacturing Capability"

BRAND PHILOSOPHY

TRANSFORMING TOGETHER

Businesses are never static. They are constantly changing. The last few years have seen decade’s worth of transformation. To keep pace with this, businesses require a restless dynamism to innovate and the confidence to make things simpler, easier and more efficient. We are rebuilding ourselves as a new and energetic company at the head of this transformation by:

- Investing in the latest technology

- Building capabilities in the most emerging areas

- Understanding our client needs

- Delivering to activate their potential

We are on a journey, with our people, suppliers and business partners - we are TRANSFORMING TOGETHER.

WHAT WE DO

Wide range of components that address the fast-moving needs of global industry

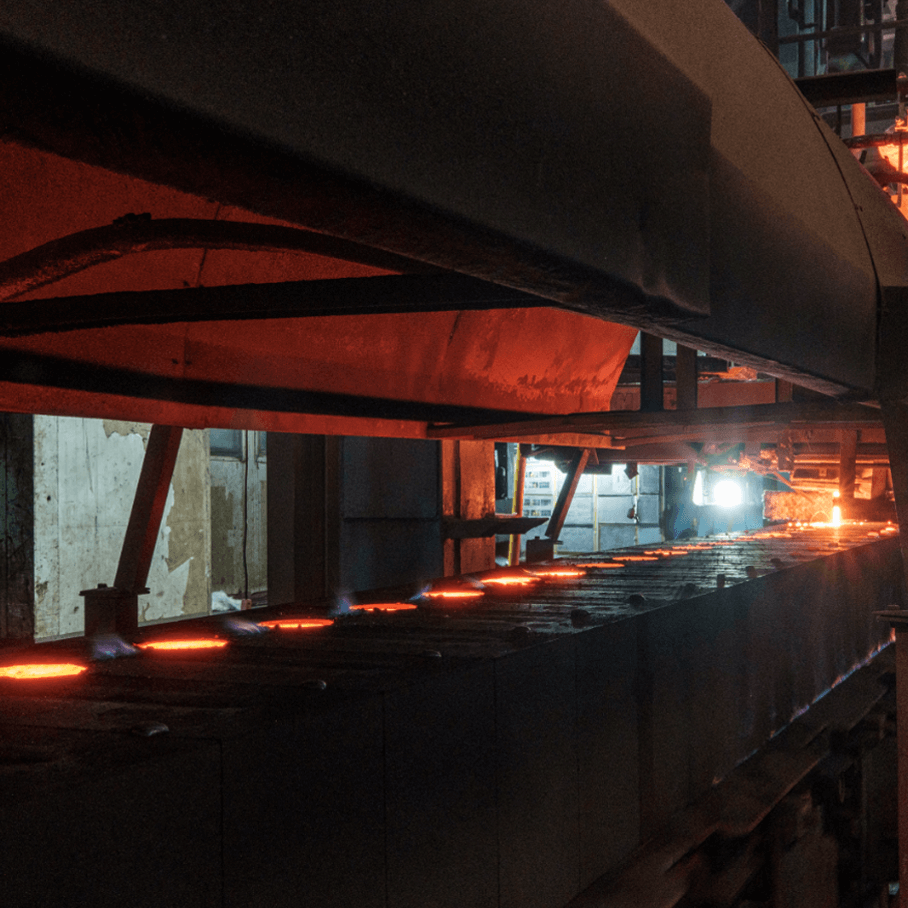

- Two ferrous foundries located in Bhiwadi.

- Capable of handling Grey Iron, SG Iron and silicon molybdenum (SiMo) alloys.

- Equipped to produce castings weighing from 0.6 Kgs to 200 Kgs.

- Integrated machining Plant at Ranjangaon.

- HPDC facility with 420 Tons to 2500 Tons. Locking Force (Idra, Zitai Presse & Buhler Make).

- GDC facility with tilting machines and shell type core shooters.

- Manufacturing plants in vicinity to auto clusters in Gurgaon, Bhopal & Hosur

- Presses upto 1350 Tons, Capable of producing a variety of precision forged parts.

- Special capabilities of handling micro alloy steels.

- Machining centers of excellence at Dharuhera, Gurugram, Hosur & Pune.

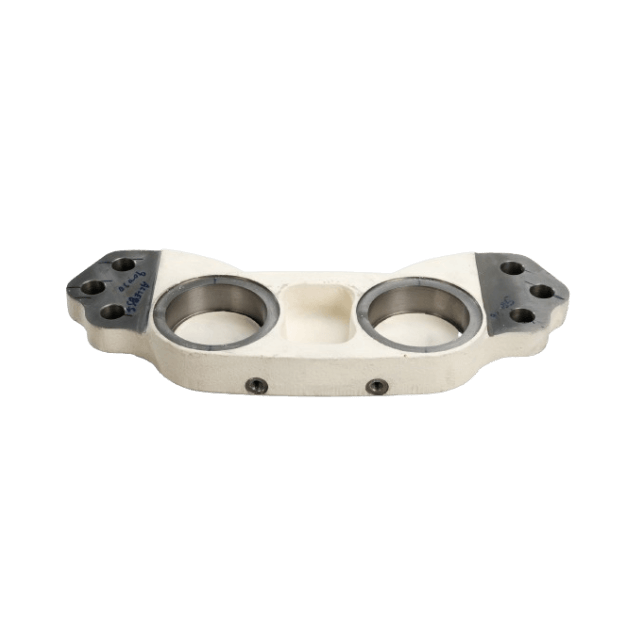

- Equipped with state of the art machining lines, providing complete capability for precision machining of full gamut of cast and forged products.

- Dedicated facilities for fractured & split connecting rods, flywheel Assembly, brake drum assembly, crankshaft & 2 wheeler stem assembly.

Turbo Charger

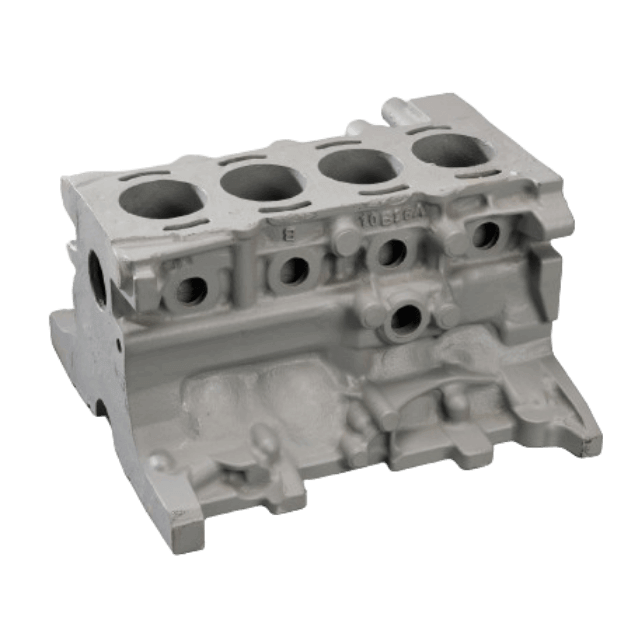

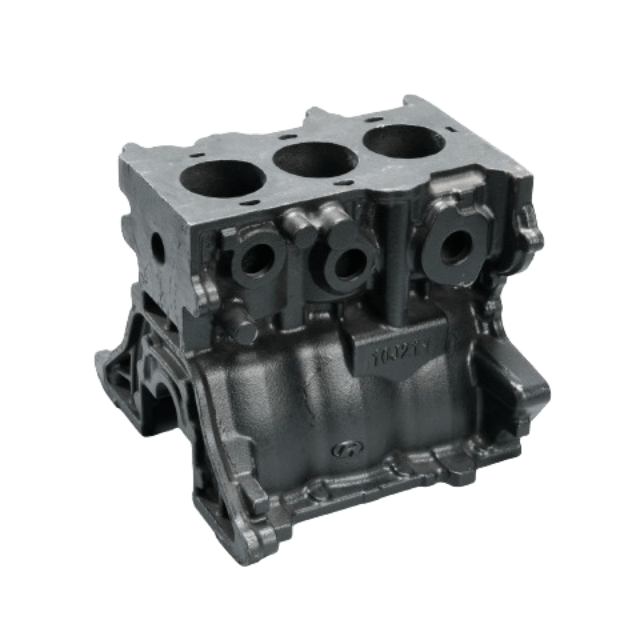

Cylinder Block

Flywheel

Cylinder Block

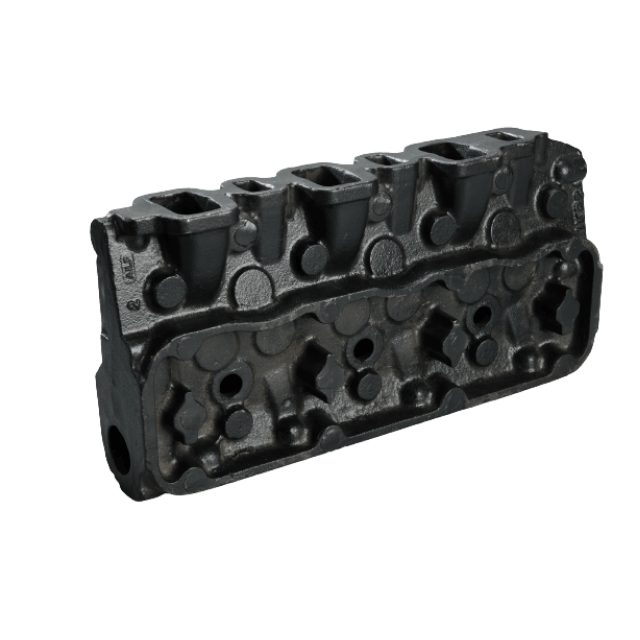

Cylinder Head

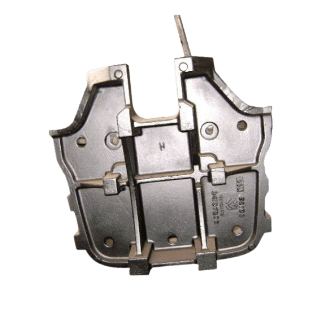

Front Axle Support

Connecting Rod

Turion Brackets

Rocker Arms

Bridge Fork Bottom

OUR ACHIEVEMENTS

Celebrated for relentless excellence